The MissionOS system operates across a wide range of industry disciplines, providing a highly configurable platform tailored to meet specific market needs.

The MissionOS system operates across a wide range of industry disciplines, providing a highly configurable platform tailored to meet specific market needs.

Maxwell GeoSystems is a mature, trusted service partner that has helped customers across the supply chain deliver highly sensitive projects within a range of challenging environments. Our “can do” attitude, rapid response, focused industry expertise, and attention to detail are recognized by our clients, resulting in significant repeat business.

MGS focuses on ground engineering, where most of the construction risk resides. The company has also undertaken several structural applications where Construction Monitoring Systems play a crucial role in tracking structural deformations and ensuring project safety. In recent years, we have expanded our services to include mining and the environmental and groundwater sectors.

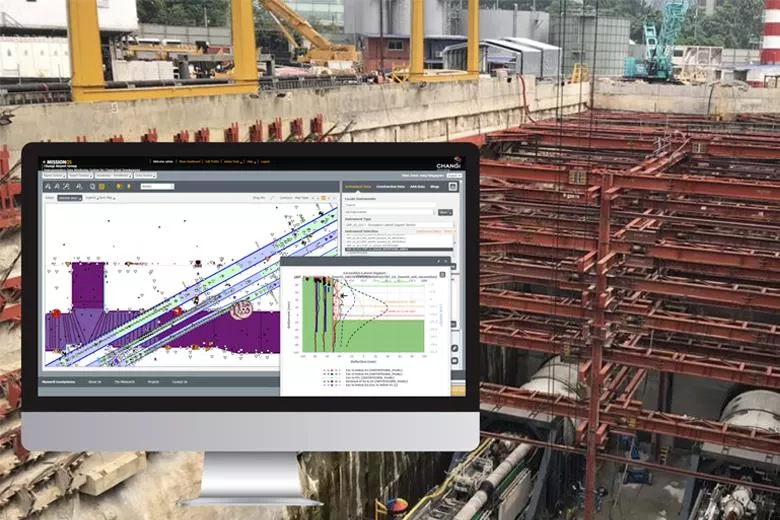

Singapore Power Cable Tunnels & Deep Tunnel

Sewage Scheme Phase 2 – Singapore

The Singapore Power Cable Tunnels and the Deep Tunnel Sewage Scheme Phase 2 represent over 150km of deep utility tunnel built in Singapore in the last 10 years.

In that time MissionOS has been the data backbone for these projects delivered directly to the owner and as a part of a novel Information Partnering Contract paid for by Owner and Contractor alike.

MissionOS provided a virtual Common Data Environment (CDE) for almost all data and became the default location for staff to find the data they needed enabling them to readily close out issues.

Efficiencies and business resilience provided by MissionOS helped bring the projects in on time and largely in budget despite the effects of Covid19.

Liantang – Heung Yeun Wai tunnels – Hong Kong

This project included a large variety of construction techniques including mechanical excavation, retained slopes and portals, drill and blast, as well as large diameter boring by Tunnel Boring Machine (TBM).

All data was required to be entered into a single Tunnel Data Management System (TDMS) to support risk management of the works.

The contractor embraced MissionOS and used it to support observational engineering of the portal and tied back wall support as well as to prove the performance of fibre reinforced concrete segment over conventionally reinforced counterparts.

The data contained within MissionOS and the assurance we were able to demonstrate was able to save the Contractor over 7 weeks of programme.

Kuala Lumpur Metro – Malaysia

Kuala Lumpur Metro, Phase 1 & 2, involved the construction of 20 new stations and 56 kilometers of new metro tunnel in very challenging ground conditions.

Previous tunnelling experience had resulted in numerous sink holes and the new project was required to provide greater assurance to the stakeholders, especially as it was driven through the heart of the CBD with several other construction projects on going.

MissionOS was chosen as the tool which could best combine all the varied data together into one environment and provide a high level of autonomy for the contractor on the project.

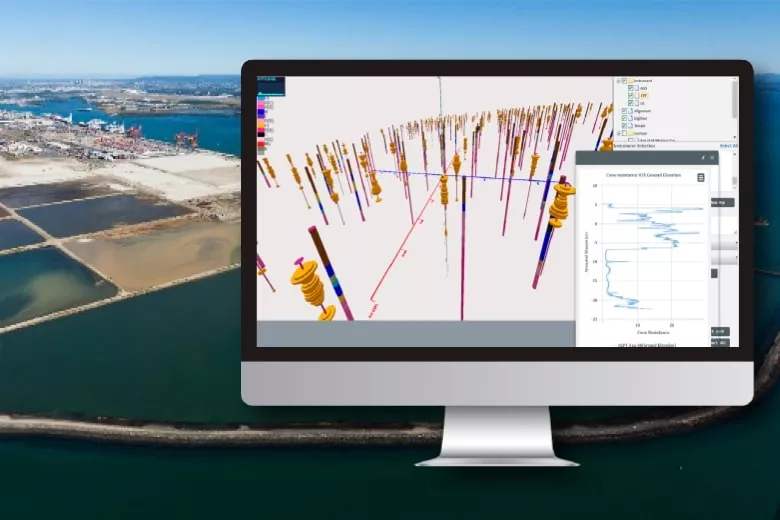

Port of Brisbane – Australia

MissionOS was used by the owner, and their engineer Coffey, as part of observational engineering trials for the new port extension built onto soft marine muds.

Different specialist contractors were invited to perform trials of techniques such as vacuum consolidation, electric potential, band and sand drains for the muds and dynamic and vibroflotation compaction for the fill.

All data for the trials was fed into MissionOS along with the results of confirmatory cone penetration tests to identify the most effective solutions ahead of the main works.

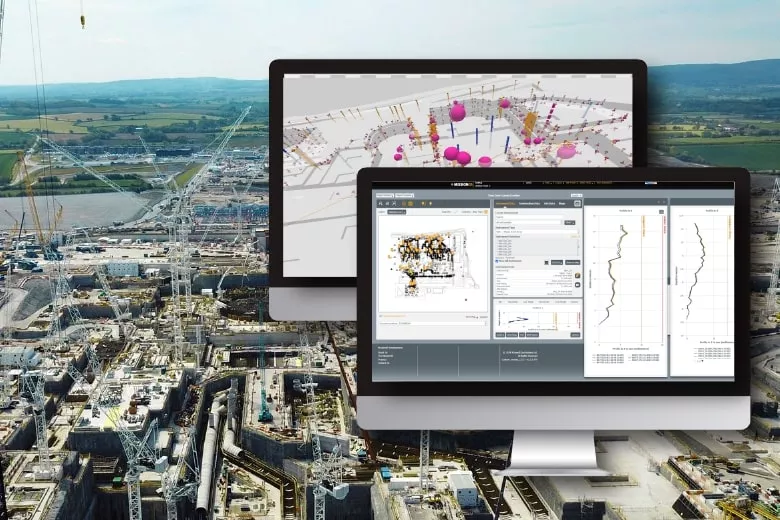

Hinkley Point Nuclear Power Station – UK

A giant earthworks operation to build the shafts for the new reactor foundations and the cooling water pipework systems just a few meters from the English Channel in the United Kingdom.

The works required close monitoring of the excavation wall deflections and support loads, as well as the uplift pressures as the excavation occurred.

All data was hosted in MissionOS over a period which will span more than 10 years.

Simem, Buildtrust – Italy

MissionOS was chosen as technology partner with Simem for creation of the Buildtrust blockchain construction settlement system.

Aimed at offsite construction Maxwell GeoSystem’s generalised configurable modular construction framework can be applied to any static or carousel factory environment.

MissionOS provides Supervisory Control & Data (SCADA) acquisition type factory production interfaces, to manage process flow in real time with sub <5 seconds latency.

The combination of SCADA, GIS and BIM in one web-based platform leads to simpler systems and more connected working.

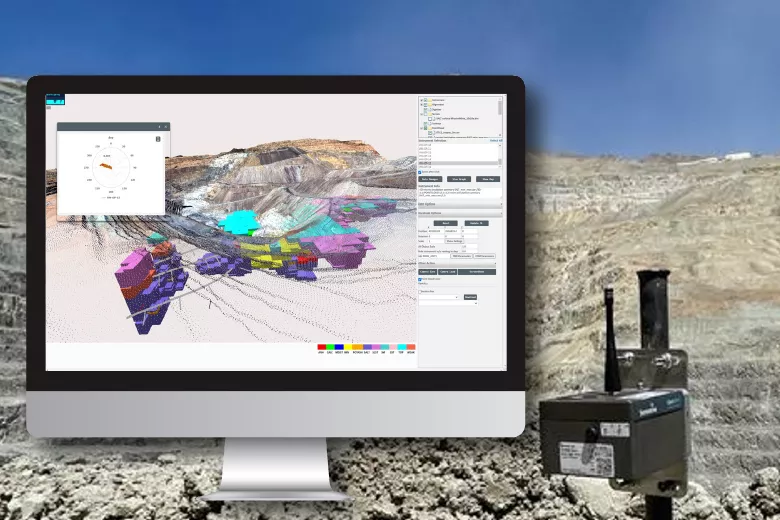

Codelco Andina – Peru

Located 4.5km up in the Andes, Codelco are mining copper in one of the world’s largest and highest mines.

MissionOS is presenting data from automated wireless tilt sensors and other monitoring to give early warning of movements in the access haulways which are critical to site productivity.

In recent years the provision of independent monitoring systems has been made compulsory for mining organisations. In addition to safety of the mine, MissionOS is being used as a foundation for mine digitalisation, improving the way mines use the data they collect to make decisions and become more efficient

Thames Tideway Tunnel – UK

MissionOS was deployed by Ferrovial Laing O’Rourke to manage all the instrumentation of bridges and heritage structures as the giant Tunnel Boring Machines (TBMs), named Millicent and Ursula, bored their way from Battersea to Tower Bridge in London, United Kingdom.

To put this monitoring data into proper context, machine data was also hosted in MissionOS in real-time to provide project stakeholders with transparency and assurance that the works were undertaken with a high degree of control.

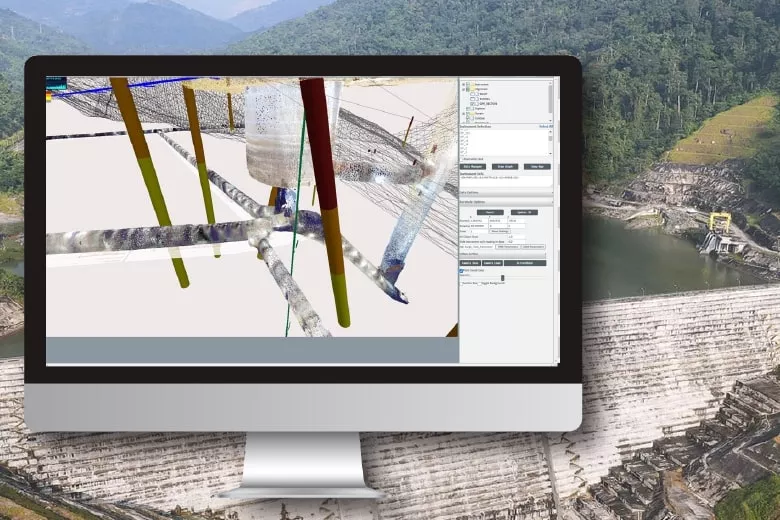

Ulu Jelai Dam – Malaysia & WaiPori Hydropower, NZ

MissionOS was deployed during the construction and subsequent filling of the Ulu Jelai dam in Malaysia to manage the instrumentation for both the dam and the surrounding slopes and access roads.

In New Zealand, Wai Pori hydropower is a gravity hydropower scheme affected by natural slope movements.

MissionOS is used to bring all the data together in one environment to understand the complex inter-relationships and help target remediation.

Cockatoo Island & Koolan Island – Australia

In “The Kimberley” of Australia, MissionOS was deployed on both projects to manage the instrumentation of seawall bunds during construction (in the case of Cockatoo Island) and during remediation recovery at Koolan Island, following failure.

The interpretation of the instrumentation results was made very difficult by the 10m tidal range in the area resulting in highly fluctuating piezometric pressures.

Maxwell GeoSystems developed an algorithm with Engineer Coffey, to remove the tidal effect from the reading to isolate the excess pore pressure, enabling safe and efficient construction.

Connect directly with a Maxwell GeoSystems support expert via email, or live chat.

Gain access to MGS Learn, the online learning platform for free, self-paced courses on product and topic-based certifications.

Discover all the latest product information on MissionOS and share your experiences with other system users.