Quickly digitise tender documents in MissionOS to provide context and streamline collaboration among colleagues, enhancing the project

Quickly digitise tender documents in MissionOS to provide context and streamline collaboration among colleagues, enhancing the project

The first thing that happens when a tender starts in your organisation is for a few gigabytes of PDFs to land in your inbox from the client. The second thing is for your colleagues in a variety of offices to start bombarding you with questions about the job because you are “the person on the ground”. What if you could quickly put this into a digital twin to provide the context of the data and make sure everyone understood the job at hand ? What if you could extract data as data from PDFs and other sources and build up the design directly in the twin using predictions published to the twin by co-workers ? You can in MissionOS using some simple steps.

Tender addenda are a constant headache and Mission is the ideal way to manage them. MGS manage the updating of relevant documents and highlight those that have changed.

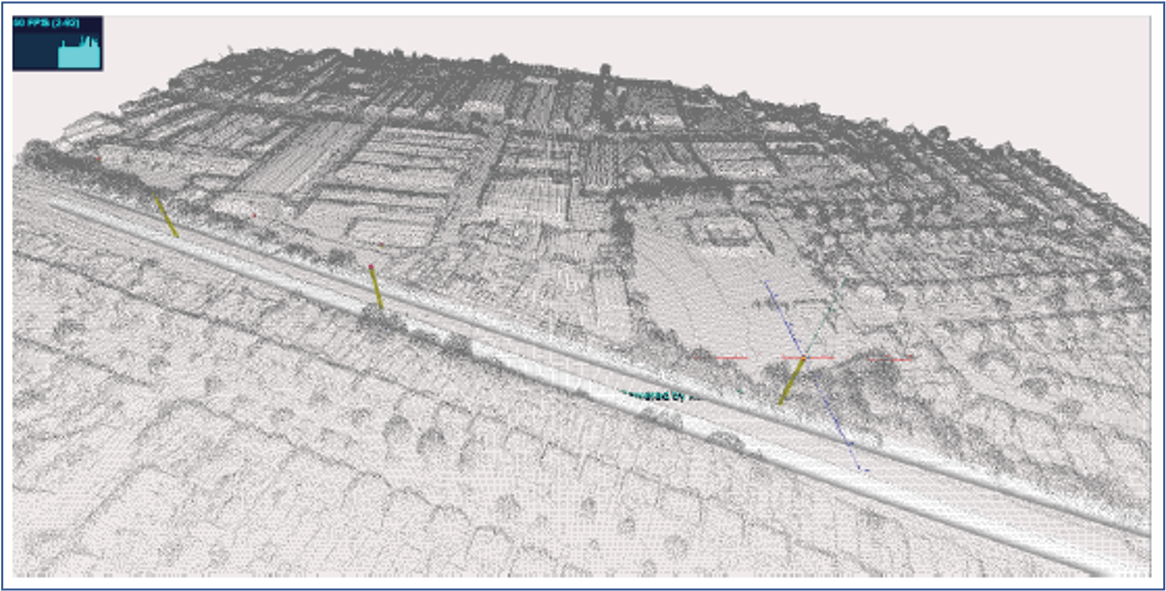

Sentinel satellite data is a free resource that can be captured to give you a digital terrain model of the area of interest to an accuracy of 3m. With processing this can also give historical background movement. Processing is quick and can be done automatically and loaded to MissionOS.

Sentinel satellite data is a free resource that can be captured to give you a digital terrain model of the area of interest to an accuracy of 3m. With processing this can also give historical background movement. Processing is quick and can be done automatically and loaded to MissionOS.

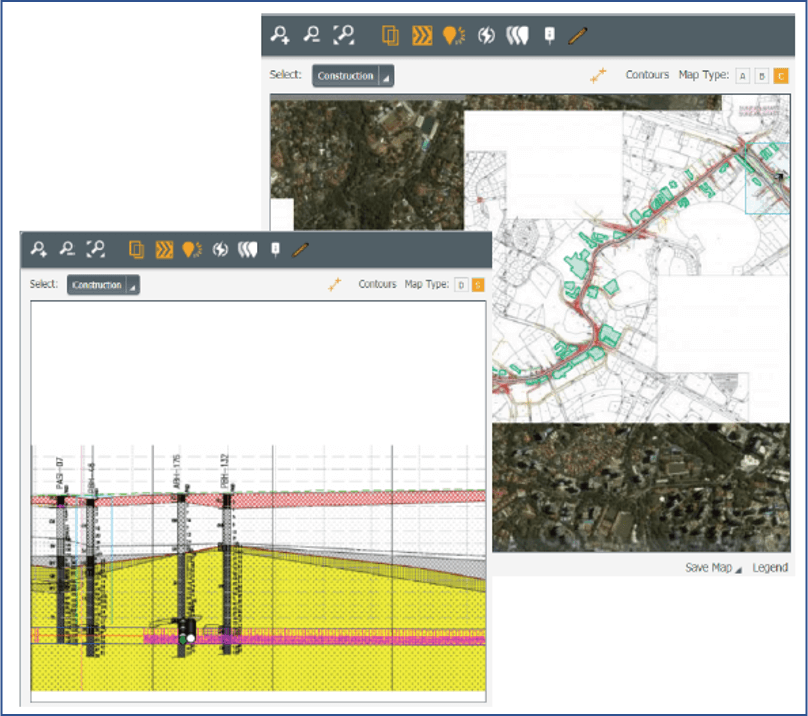

Create base maps: Users can load and georeferenced maps straight from Google or from Geology Maps or Utility maps and give context to the information.

Load the PDF drawings: Load the PDF drawings to geographic locations and tile them so they are all together. Applies to maps, long and cross sections. Use these as a canvas to start designing.

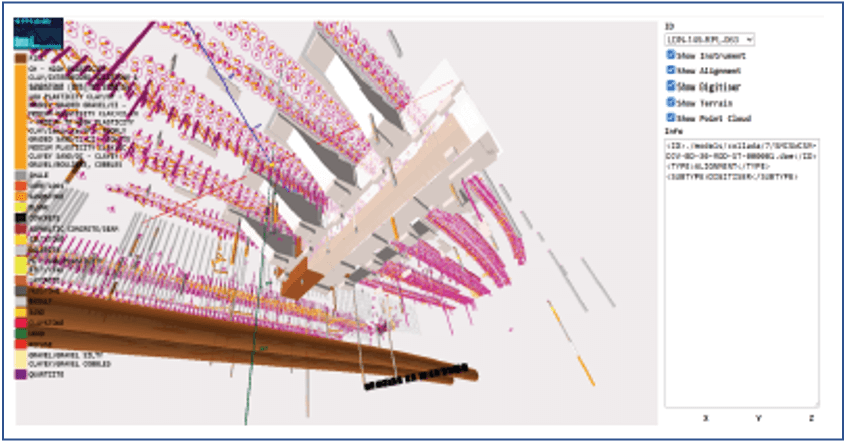

Load the outlines and alignments: Use the digital data (DWG, DRG) provided to extract the outlines and alignments into Mission. These are the project constraints on sizing.

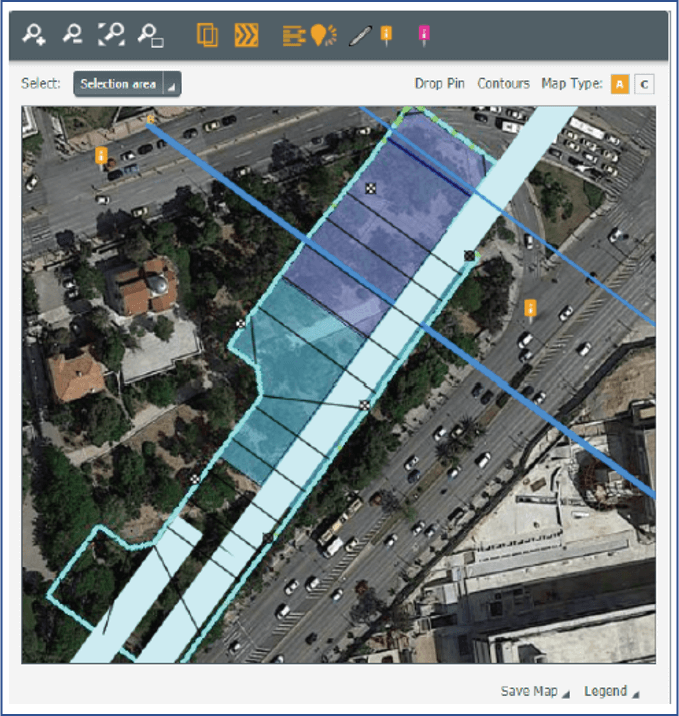

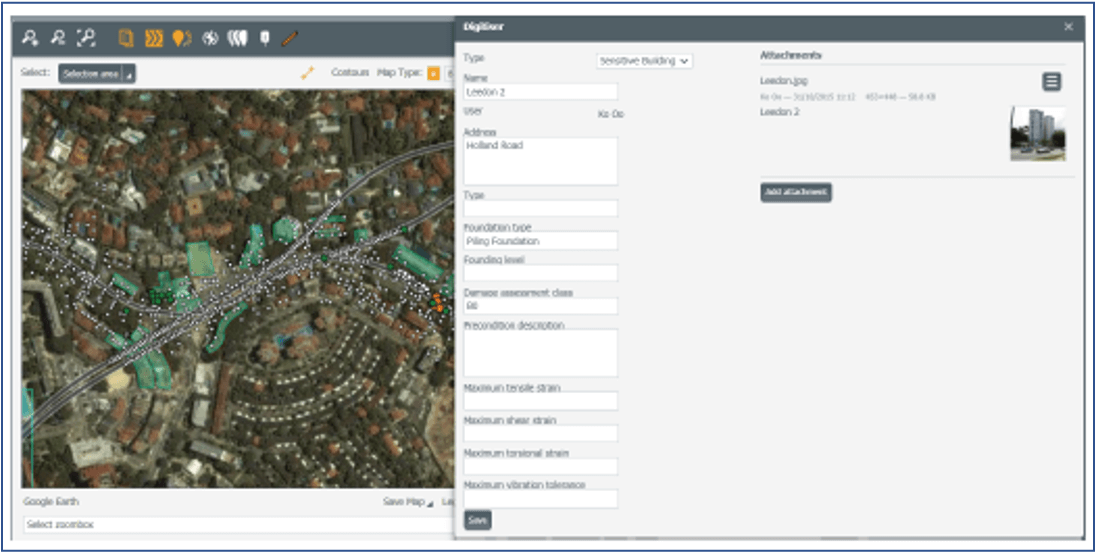

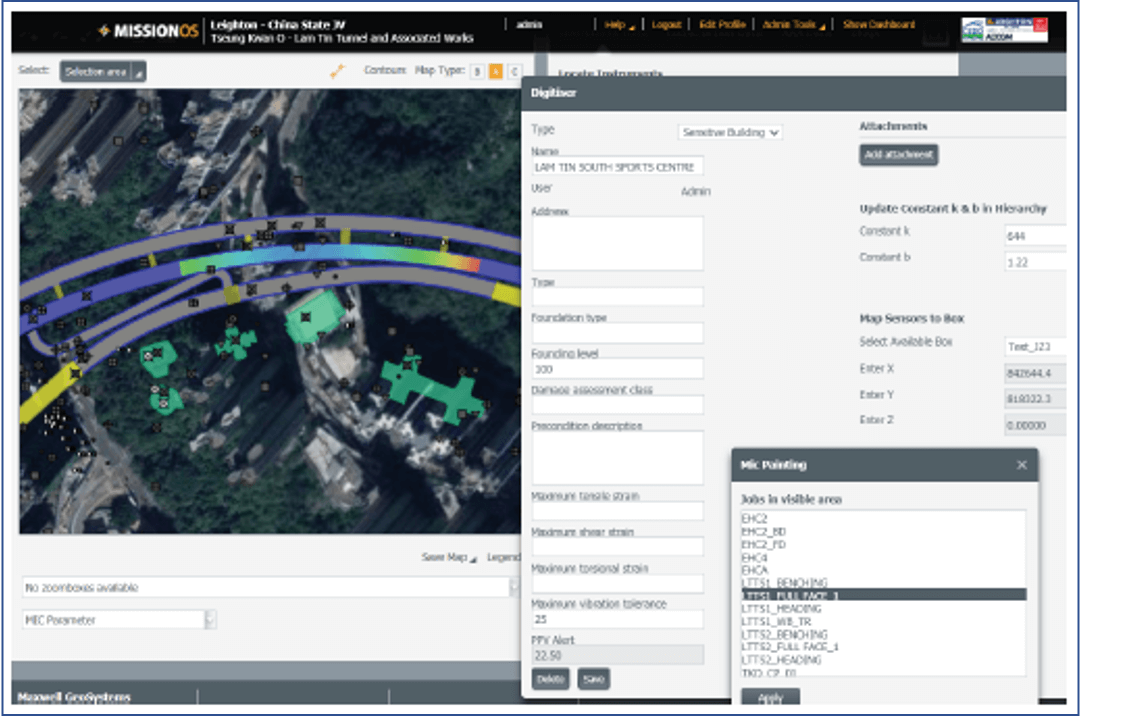

Digitise the sensitive and impacted structures: Using the built-in digitiser – draw the outlines of the various geographic hazards and sensitivities. Classify them and even apply constraints such as vibration, noise, distortion.

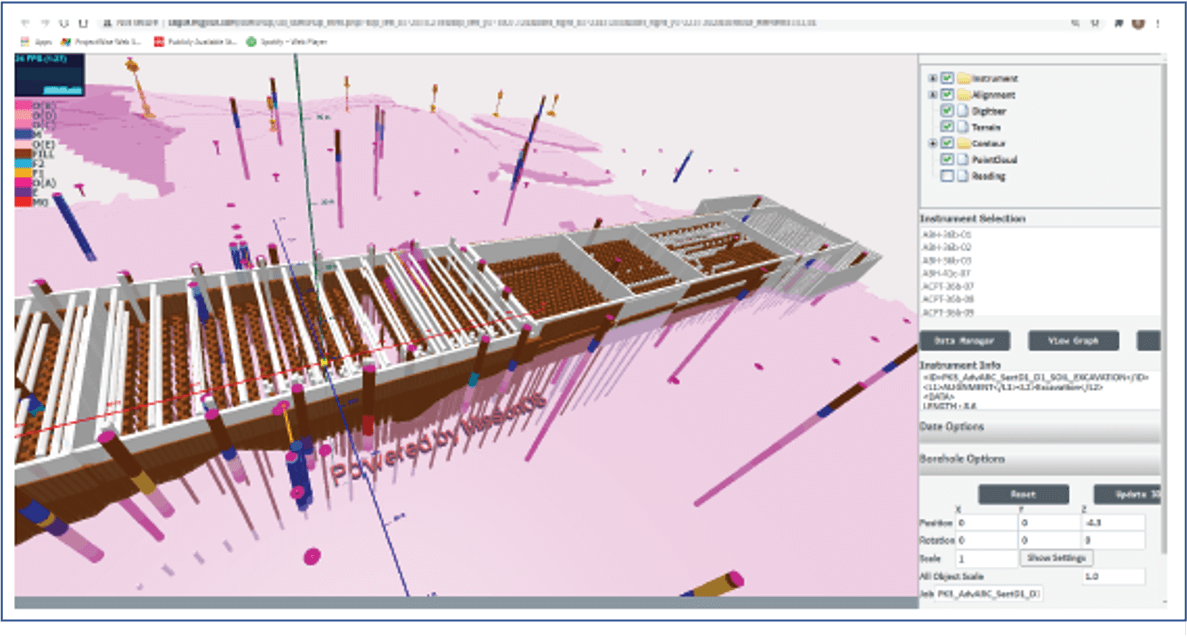

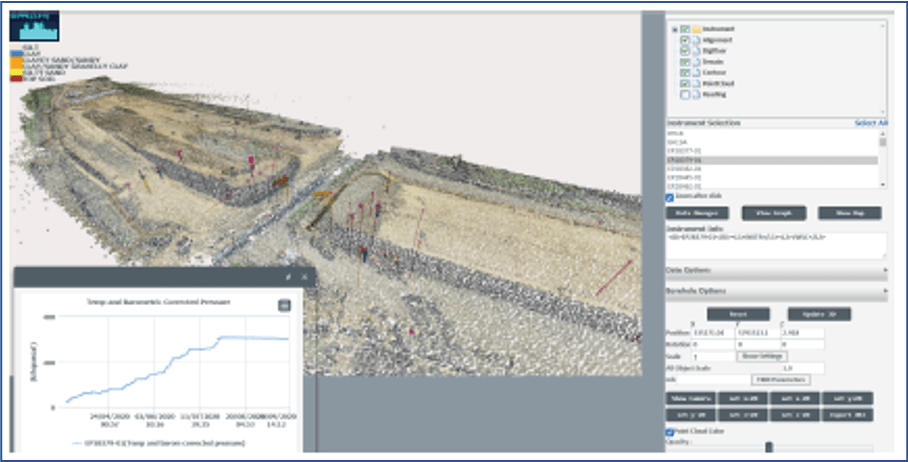

Load the Boreholes: With data in digital forms project boreholes can be loaded to MissionOS in one go. Add non project data to supplement. Audit the data to provide consistent legend coding. Add PDF paper logs to their appropriate geographic positions and easily create digital data from them for modelling.

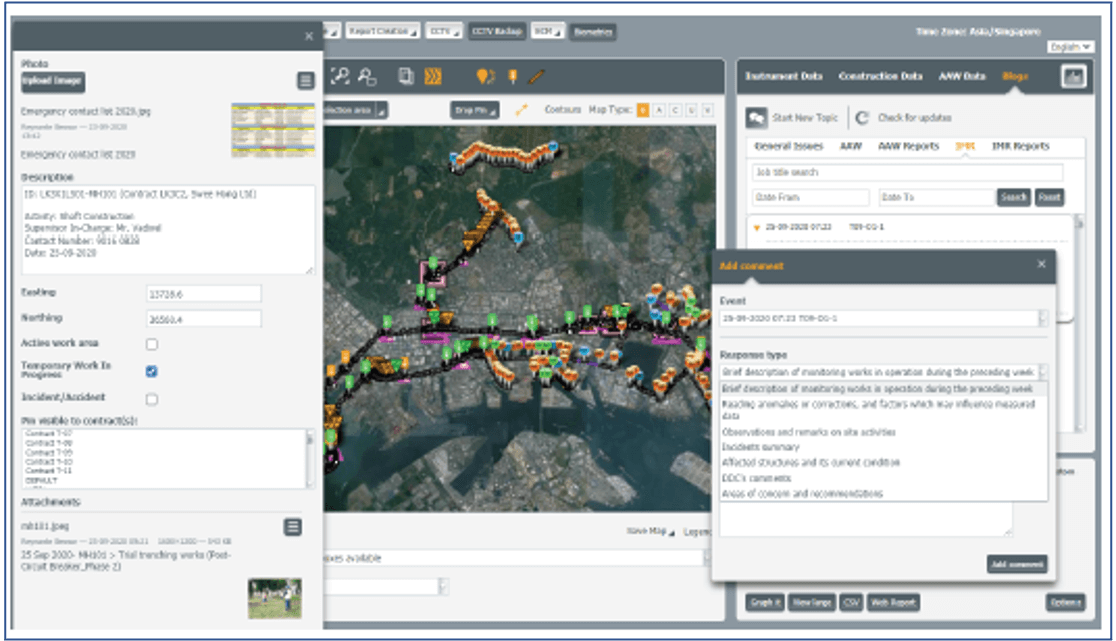

With all the data loaded on a single platform open the platform, to all collaborators on the tender. Using the hierarchy and permissions, collaborators can be limited to what they see and only tender managers can see the whole project.

Data can be highlighted to other user through the additions of pins and blog comments and email notifications are used to manage communications of changes in the data which might impact others.

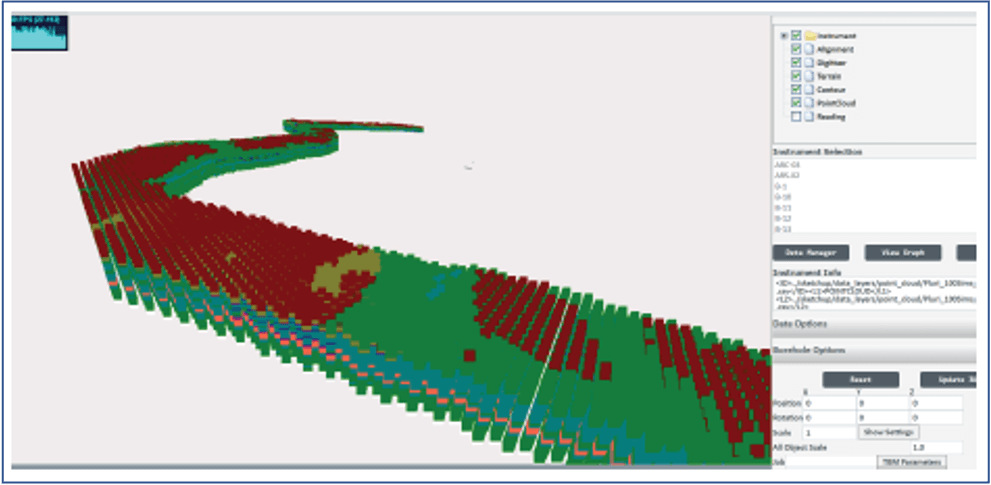

Model the geology: Using MissionOS built in gridding tools, quickly create surfaces and 3D grids for display and analysis. The tools also include Geostatistics and Kriging for risk estimation. Import models from third party modelling platforms such as Leapfrog.

Sizing: using the models test out the impact of the ground and geographic constraints on various parts of construction to define types of construction, lengths and diameters.

Programme and Sequence: utilise our huge project experience to derive progress rates vs geology and other key metrics and use these to investigate methods and sequences.

Plant and Labour lists: With sizing and sequence determined, plant and labour lists can be assigned to sites and jobs.

Load externally created prediction models: provided the models have some X parameter of relevance (chainage, level, day) models of prediction can be loaded from excel or as 2D or 3D grids.

Download the data into 3rd party software: You can export the relevant data from Mission to design packages and re-import the design predictions as grids, data files (vs level, progress).

Create prediction models in Mission: At locations of known ground conditions, you can create formulas to iteratively calculate predictions using your own methods e.g., consolidation.

Impact: Use MissionOS geospatial tools to evaluate noise and vibration impact and define limits on construction within a site boundary.

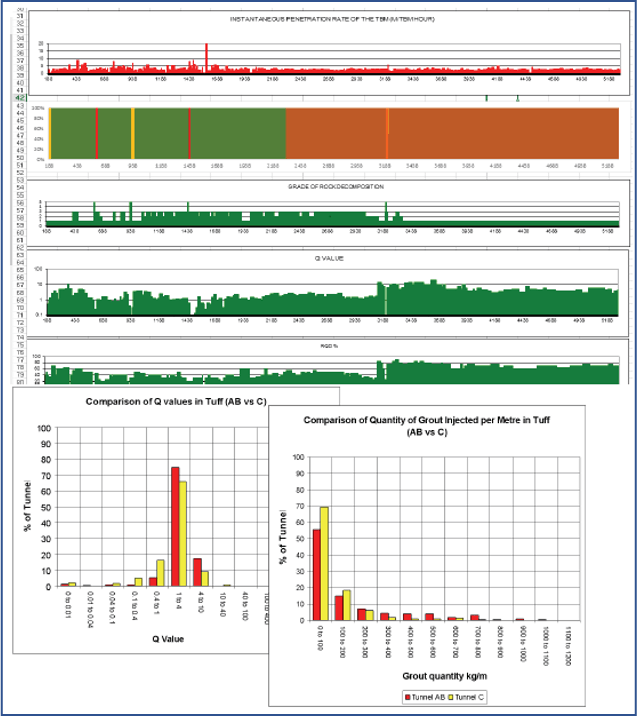

Generate production predictions based on historic data: Whilst we cannot provide our historic data, with so many projects completed we can provide advice on a variety of production statistics which can be used to predict quantities and time. With data in such detail, we can also provide advice regarding variability from which a quantified estimate of contract risk can be derived.

Create Geostatistical ground models: Geostatistical ground model simulations take the form of 3D grids which can be queried to provide a variety of estimates to support tendering including muck volumes by type, soil conditioning, cutter wear and performance rates.

Look for opportunities in the Geotechnical Baseline Report: The beauty of Geostatistics is in the accompanying data. Each simulation is accompanied by a number of statistical parameters which can be used to identify where significant variation from the baseline reports are likely allowing you to strategically price items.

Tender and post tender there is opportunity for the client and designer to identify efficiencies in the delivery of the works. This may be through alternative designs, different machinery or alternative sequences. Maxwell Geosystems work with our partners to advise owners and contractors of opportunities in these areas by quantifying where risks can be reduced through investigations, monitoring or pretreatment.

As part of the design process engineers can identify nearby noise and vibration sensitive receivers as well as structures and utilities likely to be affected by the works. The details of these buildings can be digitised directly into MissionOS and appropriate instrumentation designed with reference to this and the prevailing ground conditions. The schedule of instruments and targets depths etc can be exported directly.

Predictions from geotechnical programmes or from user defined models can be assigned to instruments and tracked against results.

MissionOS can sit right in the middle of your site processes as a single system to glue all your data together maximising the communications and effectiveness and minimising the size of the team needed to deliver the project. MissionOS has the tools to cover all areas of the site management process.

Construction Risk Management: Manage construction risks in real time with risks linked to shift and construction planning, automatic reporting of geospatial hazards and mitigation using blogs.

Programme Management: Update programmes dynamically with real statistics based on the latest data. QA/QC control: Manage site processes using our customisable construction data models and blogging systems.

Environmental Management: Why have environmental monitoring in a separate system to the construction I&M ? Combine these and save time and money.

Safety Management: Use the blogs to manage safety events, follow through with reporting processes.

Many tender deliverables from schedules to programmes can be driven directly from MissionOS or linked straight to the MissionOS data. To demonstrate processes why not make the whole MissionOS platform part of the tender submission.

It’s not easy to stand out when demonstrating that your bid hits targets for innovation, productivity and quality improvement in line with Project13 and Construction 2.0 initiatives.

Competitors will promise lots that they may never actually deliver. Implementing MissionOS as a core part of your bid shows that you are committed and are “oven ready” for the project.

BIM is mandated on many projects and whilst it is effective during the detailed design stage it is often playing catchup during construction. The MissionOS has direct links to BIM models via common data structures, scripting and ifc and can be the pivot for updating models with the latest information from the construction face.

A MissionOS platform can be created in a day. Maps and boreholes loaded in a few hours and ready for user input immediately.

Connect directly with a Maxwell GeoSystems support expert via email, or live chat.

Gain access to MGS Learn, the online learning platform for free, self-paced courses on product and topic-based certifications.

Discover all the latest product information on MissionOS and share your experiences with other system users.