Articles

Maxwell GeoSystems maintain an active library of media articles and copies of its latest contributions to trade journals.

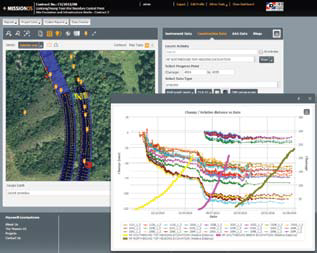

Mission Control; Monitoring Temporary Works In Tunnels

Data Systems As Part Of Partnering Arrangements

Adversarial contract terms are not a good starting point for data collaboration but on the 39 km Singapore Power cable tunnels the client took an unusual approach during the tender process requiring the contractors to invest and partner in information sharing at the highest level. The tunnels were driven using 14 TBM Tunnels in Granite rock, mixed face with decomposed soils, meta-sedimentary strata and old alluvium from 19 shafts. They were divided into NS and EW systems with 3 main contracts in each. Geology varied from highly fractured water bearing metasedimentary rocks of the Jurong Formation into Bukit Timah Granite with corestones at rock head, deep weathering layers with overlying fill and peat in places to Old Alluvium with loose fluvial sands and marine muds above in the east. The tunnels were driven from 18 no. approximately 20m diameter shafts up to 60m deep and constructed using diaphragm walls in 12 panels 3 bites. The bases of the shafts were extended by drill and blast into rock with adits and enlargements. The main drives were driven by TBMs with slurry machines used in rock/mixed face conditions and EPBMs in Old Alluvium. The permanent lining was constructed with 1m and 1.4m rings to allow tight radii to follow road alignments. This required careful segment reinforcement design.

An earlier phase 1 had been difficult with stoppages due to settlement. The Phase 2 tunnels posed many risks including sensitive structures and compressible soils. With the tunnels being deep there was a need for hyperbaric interventions to control inflow. Many of these would be in mixed geology and mixed face including many rock head transitions which had proven to be difficult in previous tunnels. The tunnels were also driven in close proximity to a variety of sensitive assets and the client needed something to increase confidence.

The IDMS Consultant

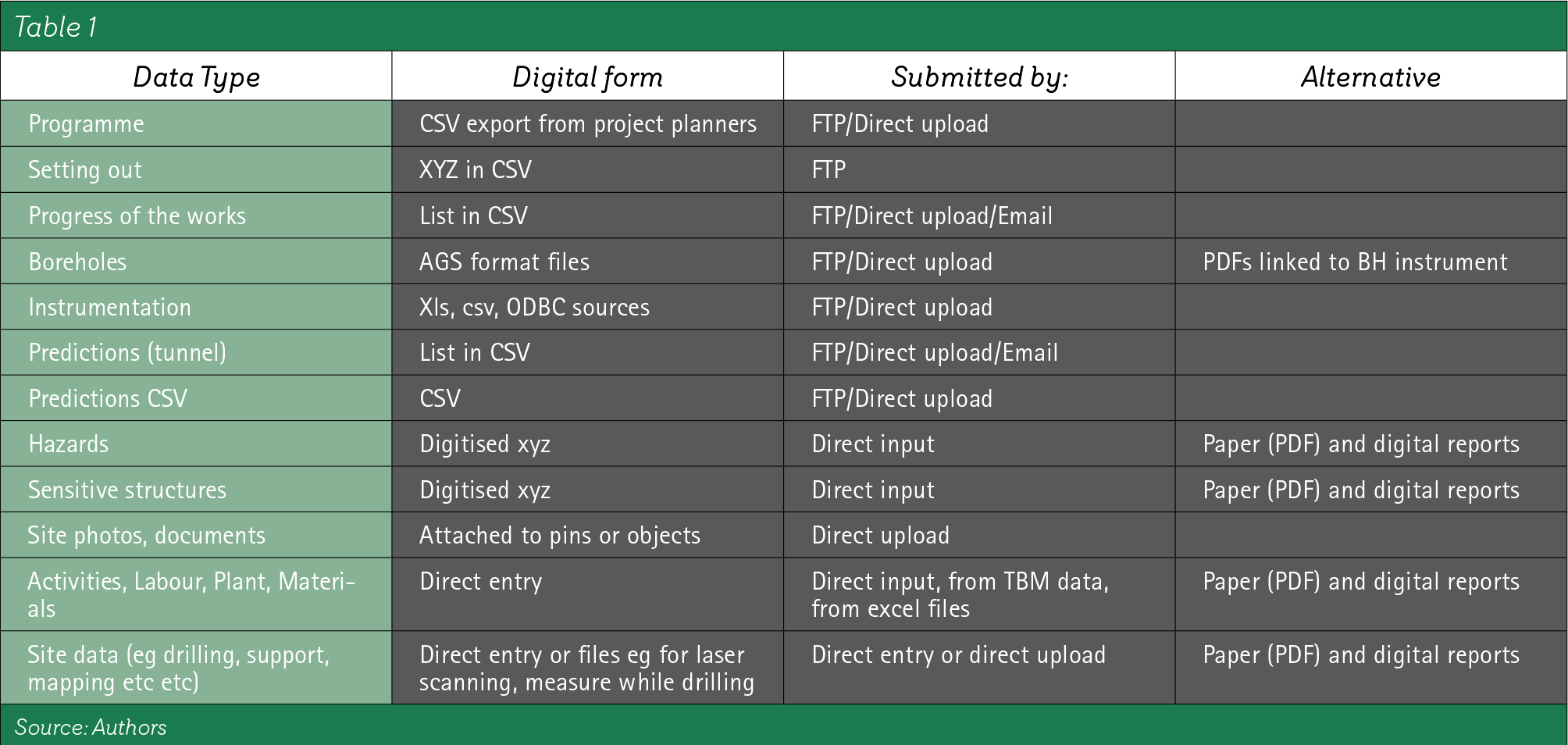

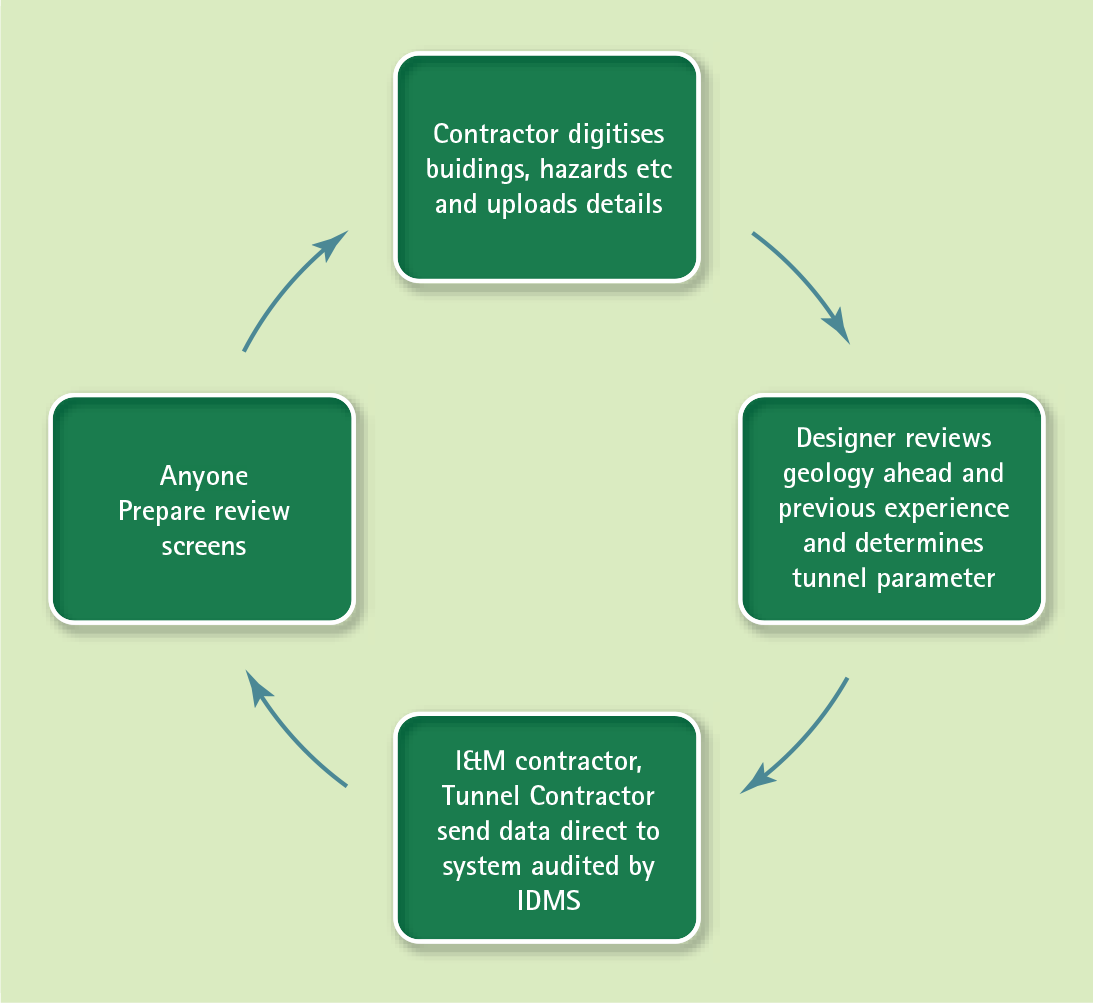

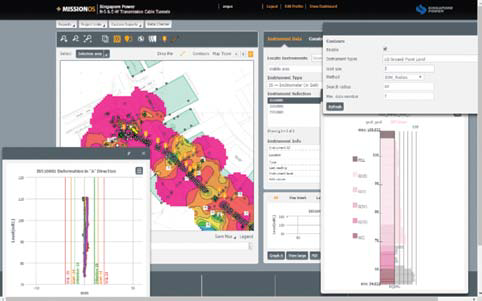

Singapore Power and their consultants decided to include information as part of the project partnering and risk sharing arrangement. A contract was prepared to select an agency to install and maintain a system for the whole project. The system took monitoring from others and independently processed information and undertook audits. All Client and Contractor parties contributed to the cost and ALL project data was loaded. It was mandated at project director level and the IDMS must be used at all meetings involving the client, consultant and contractors. The platform ultimately contained 42,000 instruments, >20 million data records, data from 20,000 rings with up to 1,300 parameters recorded at three-second intervals. The accumulated databases were many tens of Gigabits in size. Data volumes of this size were clearly impossible to be handled in spreadsheet format and the MissionOS Platform using MySQL databases facilitated data handling and enabled rapid real time feedback on the works for decision making.

Targeted Processes

Rather than simply being a repository for TBM data the system targeted common site processes aiming to make these more efficient and effective. A key requirement of all tunnel jobs is the daily TBM tunnel review meeting, where hazards and risks and forecasts of geological conditions are reviewed in parallel with the condition of surrounding monitored sensitive infrastructure. The performance of the TBM within the preceding ground was reviewed and decisions were made as to the appropriate TBM target parameters.

System Design: An Operating System For Data Not A Black Box

Key to this process was the reliable real time collation of a wide variety of data from tunnel surface and web layers with built in redundancy which allowed critical processes to continue if tunnel to surface or surface to web connections were compromised. In this way each site compute ran a virtual Linux machine and operated as a web server. Data provided at web level, surface level and TBM level was combined for full real time display. Each layer maintained a cache of data from each other layer such that if there was a loss of connectivity the ability to function was maintained. In order to get greatest benefit from the combined talents of the site team data systems needed to enable engineers to dig into the data, identify trends and relationships and express themselves by building useful reports and views which guided the risk management and design forecast process. Care was taken to allow a high degree of interactivity and customisation of the way data was combined and viewed.

Linking Data For Disp Lay And Calculation

A key requirement for the systems was for them to provide linkage between cause and effect as well as prediction and performance. To understand the context of the predictions there was also a need to link data to ground conditions both factual (borehole tests etc.) and interpreted (sections, maps etc.) The systems were able to connect data spatially (i.e. in terms of coordinates) but also against the project chainages for various elements. To do this the setting out of each main element of the works must be defined and completion targets set. Against these spatial definitions the system hung prediction information in advance of the works. Linking these data enabled the users to look at information in a new informative way. Review levels were set as proportions of design predictions and data presented to reflect design sections and sequences. Second order parameters were also be defined and calculated. This can be a simple combination of two settlement points to determine tilt or a combination of data to define key structural parameters for a building.

CAN VAS Reports: Customisable Reporting And Analysis To Facilitate Engineer’s Analytical Express Ion

Freed from the need for data manipulation in spreadsheet and word processor, engineers can stat to create comparative sheets to identify trends in the data and assist communication and forward forecasting. This is achieved using innovative ‘canvas’ screens which enable an infinite number of plot combinations to be designed. The canvas screens do away with the need for laborious preparatory work ahead of tunnel review meetings with complex screens automatically updated with the latest data for discussion. Staff members were also able to query the data and do very quickly analysis on the fly during the meeting using the MissionOS. The end result was discussion on the trends and relationships shown in all the data, not on cherry picked subsets, which support a particular conclusion. This resulted in shorter focussed meetings with better informed staff and reduced project risk.

Facilitating The Feedback Process ; Rockhead Transitions

The N-S tunnels were driven at around 60m depth and were expected to encounter several rock head transitions. Risks included the inaccurate prediction of the transition from available boreholes leading to the need for interventions in mixed face conditions and subsequent water inflow. With variable weathering and fractured zones at the margin, loss of slurry and resulting face pressure drops may result in settlements. Review of initial transitions showed that mixed face conditions were encountered at locations different to those depicted on the contractors initial design sections. Using this feedback the contractor’s increased face pressure well in advance of the transition and set a higher minimum pressure on the TBM. Interventions were carried out earlier to ensure that these were not carried out within the fractured and porous transition zone. Bulking factors were adjusted as soon as face pressures showed loss of pressure indicating the transition from full face rock. The resulting settlements were controlled effectively and improved as the job progressed. It should be noted that these screens were also available to the machine operator underground and can be updated continuously with new borehole information throughout the course of the job. Each screen is interactive so that upcoming boreholes can be interrogated.

Control Of Face Press Ures And Muck Balance

Machines may have anywhere from 3 to more than 10 pressure sensors on the face and conventionally these are displayed as a series of line graphs. Since there is considerable pulsing of the overall face pressures during the mining process these are difficult to interpret. However, plotting these as face pressure distributions provides a much better insight into the normal conditions and aid recognition of exceptions which may occur due to slurry loss, change in EPBM muck condition or a malfunctioning sensor. Similarly the muck balance is an extremely difficult parameter to measure and control. Putting the data together on one set of screens enables the user to see geology, settlement and design target volumes and see the grout volumes inject in their correct positions. Such rapid assimilation and presentation enables TBM engineers to react to over-excavation by increasing grouting pressures and volumes in appropriate places to deal with loosening before it has migrated to the surface.

Alarm Response And Feedback – The Kuala Lumpur MTR Experience

The Kuala Lumpur (KVMRT) metro required the construction of 12km of twin tube tunnel through karstic limestone and sandstones/siltstones of the Kenny Hill Formation. These were arranged in stacked and side by side with a transition in between. The overlying deposits were highly variable and compressible. To mitigate the risk of ground and structure movement the consultant set out a nine point plan for managing alarms on the Job. This required all members of the contractor’s team to contribute to the process within a defined period of time. With more than 2,500 alarms this process became a significant challenge and the contractor sought ways in which this could be optimised. The MissionOS alarms and alerts were sent via SMS and email as standard and to this we added the option to send data to weblogs which acted as an on-line in-message board to manage the responses. Behind this, logic was added to allow the definition of groups of users responsible for particular actions and the system set up to control and close out the process. This worked exceptionally well and built on site staff’s familiarity with the social media platforms. As a consequence the system became a truly active risk management tool capable of turning round live reports within a matter of one or two days rather than weeks as had been the case. Each report was now just the end product of a thread of observations and responses which was tracked through to completion of the job.

Observational Engineering On The Liantang – Heung Yuen Wai Boundary Crossing

The Liantang Heung Yuen Wai boundary crossing comprised some 5 km of tunnels driven at large, > 14m diameter, using a combination of drill and blast, mined and TBM tunnels through hard rock and residual soils in Hong Kong. A full description of the project was outside the scope of the presentation but rather it focused on the observational engineering undertaken by the contractor at the north portal in order to mine an initial curved section at a diameter of 20m. The objective of the approach was to address design uncertainties as to the performance of the residual soils and transitional (rock soil) materials and to establish whether steel invert struts could be dispensed with saving time and money.

Complex Portal Construction In Difficult Ground

The 20m wide mined tunnel spans were constructed by heading and bench. Strain gauges were installed on steel members in sidewall and crown positions to monitor total load and the bending generated in the support beams as the bench and then the adjacent tunnel were excavated. Strain gauges were also installed in 9 locations along 7 rows of anchors drilled 45m into ground to tie back a 22m high bored pile wall. Deflection was measured using inclinometers, 3D prisms and extensometers. The MissionOS system was instrumental in enabling the comparison of data in real time and resulted in rapid agreement of performance and modification of design.

ISegment – Wireless Monitoring Of Temporary Loads During Erection

In addition to the portal construction the contractor needed to be innovative in his approach to the TBM tunnel since this would need to be broken out and enlarged from 14m to 20m for line of sight requirements. The contractor proposed the use of fibre reinforced segments over conventional reinforcement since these would be significantly cheaper and easier to break out. The concern was that these segments might not be suitable for the final lining since construction loads from the thrust rams were expected to be high resulting in cracking under high shear forces around the rams and between adjacent segments. A minimal conventional reinforcement was designed to cope with contact loads and the remaining reinforcement was provided by fibres. A novel approach to instrumentation of the segments was designed to capture fully the dynamic loads during the construction process. No external cabling was allowed and, to manage power consumption, vibrating wire gauges were not considered. Laboratory foil type gauges were used instead. These were mounted on elastically transparent fibreglass frames and linked to signal conditioning and analogue-todigital conversion modules (SGM) which were placed inside the concrete. The SGM cabling could be reduced to a single digital data bus (RS485) and directed to a small data logger which can record for long periods using conventional D cells. Battery life was dependent on polling frequency temperature and other ambient conditions. Initially data was polled every minute and up to 10 seconds during key periods.

Automated Design Feedback On Victoria Station Upgrade

The application of automated design feedback was trialled as a pilot at Victoria station upgrades in London. Here shaft excavations for step free access were made within 300 mm of existing operating tunnels. The SGI cast iron linings with simple knuckle joints are highly sensitive to lateral displacements. Each day the results of automatic monitoring by total station and Bassett convergence arrays were down loaded manipulated and back calculated to give structural parameters for the lining. This process was repetitive and laborious and was a clear target for automation. In the pilot, the data was provided to the MissionOS system and after preprocessing to give diametric movements the results were exported to a simple FE solver to calculate the bending moments and displacements at the joints. The final display linking daily progress, observed movements, predicted movements and derived structural parameters was set up within the MissionOS canvas screens.

Conclusions

The work on these projects demonstrated how effective systems targeted at site management processes can lead to significant efficiencies and improvement in response time, transparency and control giving a reduction in project risk. Management of data within web based structured data repositories means that data is always available for use and presentation reports can be produced and formatted as required.